A wide range of products for each industry

Primary Products:

- Homogenized AlMgSi bars

- Aluminum and aluminum alloy slabs

- Aluminum and aluminum alloy wire

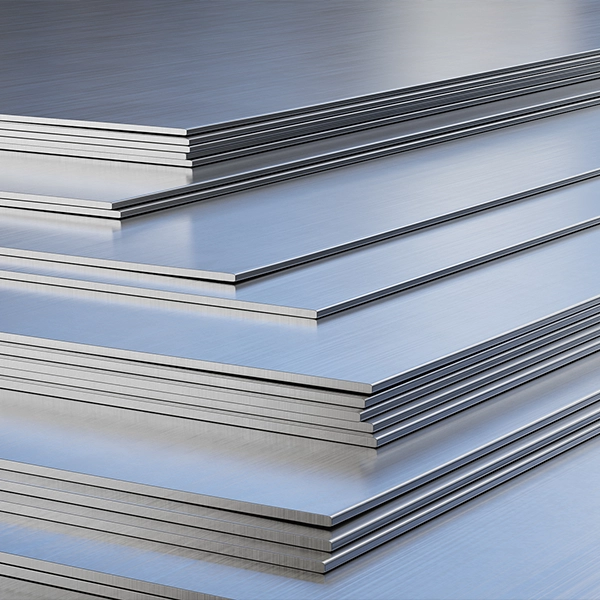

Processed Products:

- Aluminum and aluminum alloy plates (both heat-treated and non-heat-treated)

- Aluminum and aluminum alloy sheets and strips

- Coated aluminum alloy sheets and strips

- Extruded profiles